Flange

Facing Services

Professional on-site flange resurfacing to restore sealing integrity, keeping your equipment leak-free.

Restore Flange Condition Anywhere

Damaged or corroded flanges can cause leaks, equipment failures, and unexpected shutdowns. Our professional flange facing services restore sealing surfaces back to original specs, helping you maintain safety and compliance. We have the ability to service most flange types and sizes in their current place.

Our experienced technicians work on-site with portable machining tools, minimizing downtime while ensuring your flanges are ready for reliable, leak-free performance.

Trusted for Critical Connections

PFP provides flange facing services for critical equipment across industries such as aviation, oil & gas, power generation, chemical processing, pipelines, refineries, and much more – including:

- Pipelines

- Pressure Vessels

- Heat Exchangers

- Storage Tanks

- Process Piping

- Valves and Fittings

Our team of experts respond rapidly to emergency situations, making PFP the most reliable source for filtration equipment and related services. Protect your equipment and operations – give us a call to find out how you can stay up and running in compliance with industry standards.

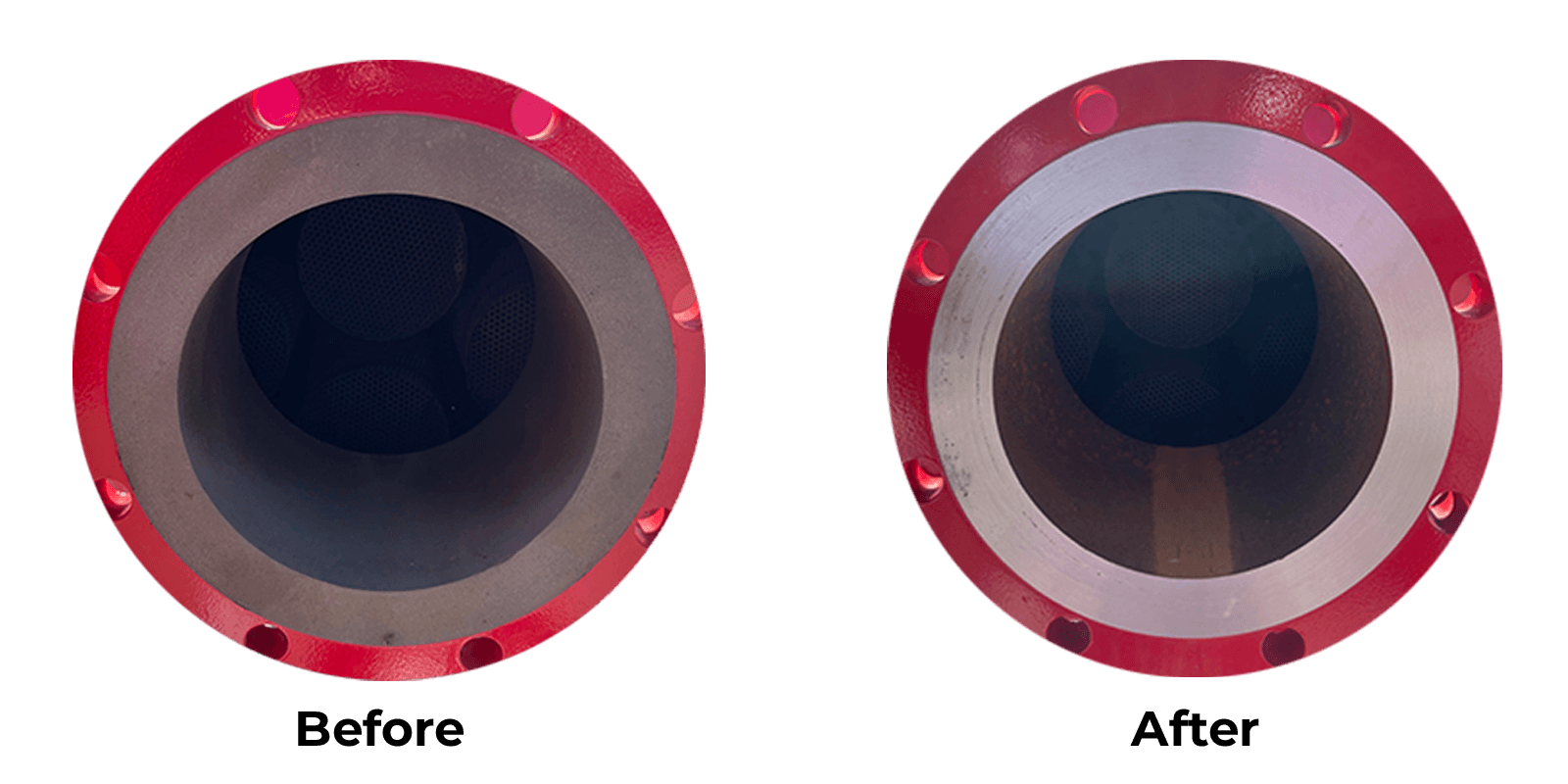

Results You Can Rely On

With over 30 years in the industry and 250 years of collective experience on our team, we understand that secure seals are non-negotiable. Our before-and-after results speak for themselves, helping you trust that every connection will hold strong when it matters most. Let PFP help you protect your equipment and your team.

Get in touch to see the difference for yourself!