A customer of ours was commissioning a new NGL distribution line. After gaining an accurate understanding of the application and quality goals, I was able to specify and deliver the appropriate filter vessels and elements within a few days. The most difficult challenge for our customer was time, or a lack there of. The immediate demand to provide product required a solution…FAST!

An additional challenge was a higher than standard design pressure of 285 PSIG. Fortunately, PFP maintains a significant rental fleet ranging from portable hydraulic filter carts to high flow pipeline filter vessels.

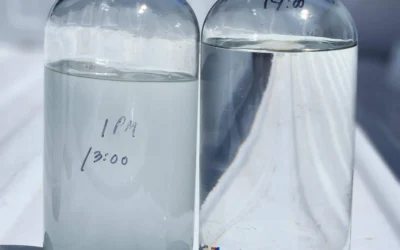

To guarantee the delivery of high quality product, a three-stage system with specific filtration technology was required to protect from potential contaminants…

Particulate Filter: Removal hard particulate contamination such as pipe scale and dirt

- Coalescer/Separator: Aids is the coalescing and removal of water droplets

- Clay Treater: Absorption of chemical contaminates such as drag reducers, color bodies and surfactants.

Currently the system is operating perfectly and will continue to achieve quality goals until we build and ship the brand new system!

Call us to discuss how we can help you achieve and maintain your high quality product goals!