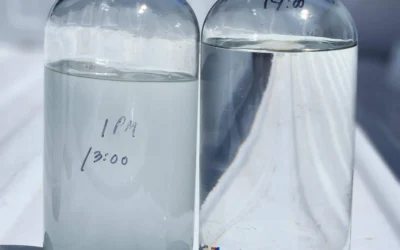

A refinery contacted us recently that required a filter system to transfer 55 gallon drums of ISO 100 oil to their storage tanks (see attached picture).

They wanted to filter the oil prior to it entering the tanks. After getting more information on the application, we recommended using one of our Spin-On Filter Panels. We decided to utilize pneumatic pumps, instead of our standard 110 Volt electric driven pumps and motors, on the filter panels because the systems were going to be installed in hazardous areas, Class 1 Div 1 or 2.

They wanted to filter the oil prior to it entering the tanks. After getting more information on the application, we recommended using one of our Spin-On Filter Panels. We decided to utilize pneumatic pumps, instead of our standard 110 Volt electric driven pumps and motors, on the filter panels because the systems were going to be installed in hazardous areas, Class 1 Div 1 or 2.

The pneumatic pumps are ideal for hazardous areas because they are powered by compressed air, making them intrinsically safe. In addition to being intrinsically safe, the pneumatic pumps have many other advantages. They are self-priming allowing for high suction lift even at dry start-up conditions. They also have the ability to run dry without damage, which allows for weary-free operation, since there is no risk of damaging the internal components.

The pneumatic pumps are ideal for hazardous areas because they are powered by compressed air, making them intrinsically safe. In addition to being intrinsically safe, the pneumatic pumps have many other advantages. They are self-priming allowing for high suction lift even at dry start-up conditions. They also have the ability to run dry without damage, which allows for weary-free operation, since there is no risk of damaging the internal components.

We designed the Pneumatic SFP Filter Panel, aka “The Panimal”, using a Versa-Matic pump and also installed a ball valve as a kickback/relief so the operator can run the pump while controlling the fill rate remotely via a valve located at the equipment being filled. We utilized Viton® Seals throughout the system in combination with a 6 micron micro-glass ABSOLUTE rated Beta 1000 Spin-on Filter and a Water Absorbing Spin-on Filter to remove any free water that may be present.

The customer also requested a drum adapter similar to the crude sketch they provided (see attached). We ended up providing a recirculation adaptor kit that incorporates quick-disconnect fittings and a desiccant breather for the drum. This provides a sealed system to protect oil from external moisture and harmful particle contamination. It also allows them to recirculate the oil in the drum before transferring to the storage tanks or equipment, if necessary.

The customer also requested a drum adapter similar to the crude sketch they provided (see attached). We ended up providing a recirculation adaptor kit that incorporates quick-disconnect fittings and a desiccant breather for the drum. This provides a sealed system to protect oil from external moisture and harmful particle contamination. It also allows them to recirculate the oil in the drum before transferring to the storage tanks or equipment, if necessary.

The customer initially ordered (2) two “Panimals” for their facility. After using the Filter Panels for a short period of time, they had so much success, they decided to order (4) four additional systems. The refinery is now set up with Pneumatic Spin-On Filter Panels on all of their storage tanks.

Call us for more information on our portable filtration systems for transferring oil from your drums to your storage tanks! We can customize the filtration systems to fit your needs.