In hospitals and healthcare centers, backup power isn’t a luxury—it’s a lifeline. When the grid goes down, emergency generators are the last line of defense keeping life-support machines, surgical suites, and critical care units running. But even the best generator is only as reliable as the fuel feeding it.

This is why fuel polishing is one of the most important maintenance services for facility managers at critical establishments, especially healthcare centers and hospitals.

How Fuel Becomes Contaminated at Hospitals & Health Care Centers

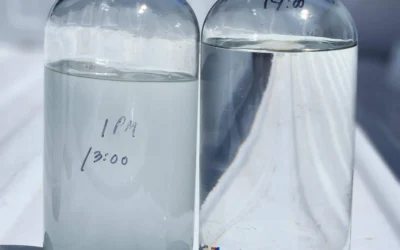

Over time, diesel fuel that has been sitting in long-term storage will degrade in quality. Water seeps in, particulates settle, and microbial growth forms—turning a stored energy source into a silent liability. Left unchecked, contaminated fuel can clog filters and corrode critical system components, ultimately causing a costly generator failure when your facility needs it most.

Fuel polishing is a preventative process designed to restore and maintain fuel integrity. It works by circulating the stored fuel through a series of filtration stages, removing water, sludge, microbial growth, and debris. Think of it as a deep clean for your fuel and fuel tank.

Fuel Polishing vs. Fuel Replacement

This process is a cost-effective alternative to fuel replacement. Replacement, while effective in cases of severe contamination, is expensive and time consuming. Not only are facility managers paying for brand new fuel (that is often unclean upon delivery), they are required to meet strict and costly requirements regarding the disposal of old, contaminated fuel.

Compliance with Fuel Standards

Fuel cleanliness has everything to do with compliance. The ASTM D975 (American Society for Testing and Materials) standard outlines the specific criteria diesel fuel must meet to be considered safe for use in engines, including emergency generators. Falling short of this standard could mean putting patients and staff at risk when the lights go out.

Section X2.6.1 of ASTM D975:

“A plan for monitoring the quality of bulk fuel during prolonged storage is an integral part of a successful program”

Section X2.6.2 of ASTM D975:

“Stored fuel should be periodically sampled and its quality assessed”

Section X2.7.1 of ASTM D975:

“Contamination levels in fuel can be reduced by storage in tanks kept free of water, and tankage should have provisions for water draining on a scheduled basis”

Benefits of Routine Fuel Polishing for Hospital Generators

Routine fuel polishing, combined with regular testing for ASTM D975 compliance, is the best way to avoid that risk. By monitoring fuel quality and acting early, hospitals can guarantee that their generators will perform when needed—no surprises.

For healthcare facilities, it’s not just about meeting codes or checking boxes—it’s about protecting lives. Clean fuel is critical power. And fuel polishing is how you keep it that way.

Fuel needs polishing? We'll come to you.

Our mobile fuel polishing services are designed to keep your emergency power systems compliant, reliable, and ready—right where you are.