We received a call from a large paper mill customer who had a high percentage of water in their oil reservoir. They were looking for an immediate solution to reduce their downtime and prevent equipment failures. Before we could offer them a solution to their problem, we needed a little more information on the application. We asked them a few basic questions:

- What is your current ISO Code?

- What is your target ISO Code?

- What is your reservoir capacity?

- What is the % of water ingression?

- What is the target moisture content?

It turns out that their oil reservoir had a 500 gallon capacity and a high percentage of water ingression. After getting the answers we needed, we determined that we had the perfect size Vacuum Dehydrator in our Rental Fleet to meet their needs. We also equipped the dehydrator with a 6 micron Beta 1000 rated particulate element to help hit their target ISO Code.

The customer placed the order and we were able to deliver and get the unit installed in less than 24-Hours.

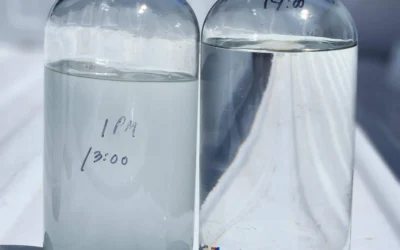

After installing the Vacuum Dehydrator, the paper mill saw an immediate reduction in both their water ingression and ISO Code. It worked so well, they have decided to continue to rent the dehydrator while they complete repairs to their cooler unit.

After installing the Vacuum Dehydrator, the paper mill saw an immediate reduction in both their water ingression and ISO Code. It worked so well, they have decided to continue to rent the dehydrator while they complete repairs to their cooler unit.

Are you interested in learning more about maintaining your oil quality? Give us a call or check out or website, www.pfpusa.com, for more information on our Vacuum Dehydrators or other portable filtration equipment. We’ll be sure to help you improve your oil quality, and we’ll save you time and money in the process.