Refinery Filtration Solutions

PFP delivers high-performance filtration services and equipment rentals for refineries and petrochemical facilities across the U.S. Keep your operations online, compliant, and contaminant-free.

On-Site Filtration Services

Refinery operations run on tight margins and tighter schedules—there’s no room for contamination, downtime, or off-spec product. PFP delivers on-site filtration services that keep your systems clean, your throughput consistent, and your team focused.

Our field crews specialize in high-flow fluid filtration, hydrocarbon separation, and critical system protection across all stages of refinery operations. Every solution is tailored to your process conditions, flow rates, and compliance requirements—delivered on-site, on time, and ready to perform.

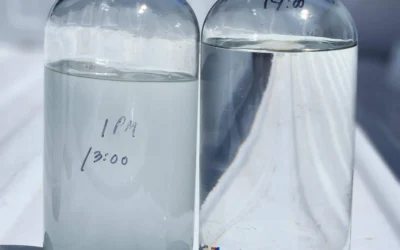

Contaminant Removal

Filtration systems engineered to capture solids, sludge, and moisture from process fluids—protecting sensitive equipment and keeping production uninterrupted in critical refinery systems.

Hydrocarbon Separation

Carbon and coalescing filtration systems separate hydrocarbons from amine and glycol streams, reducing foaming, improving chemical performance, and protecting your gas treating systems.

Turnaround Support

Rapid-response crews and mobile units ready for planned outages or urgent upsets—restoring fuel quality, flushing systems, and getting operations back online fast.

Refinery Filter System Rentals

PFP supplies refinery-grade filtration rentals engineered to meet or exceed API, ASME, and ISO performance standards. Our equipment supports critical applications including fuel recovery, hydrocarbon polishing, process fluid filtration, and off-spec remediation—ensuring operational reliability and environmental compliance.

We offer a wide range of high-flow vessels, coalescers, carbon systems, and custom skids tailored to meet exact process specs, flow rates, and fluid compatibility requirements. Every unit is field-tested, maintained to refinery standards, and available for rapid deployment during turnarounds, upsets, or routine maintenance.

Coalescer-Separators

Multi-stage filtration units that efficiently separate water and emulsified liquids from fuel and gas streams. Used to protect downstream equipment and maintain fluid quality in demanding refinery applications.

High-Flow Filter Vessels

Designed for large-volume fluid streams, these vessels remove suspended solids from hydrocarbons, water, and process fluids. Essential during turnarounds & startups or ongoing filtration of critical refinery systems.

Carbon Vessels

Activated carbon filtration systems engineered to remove hydrocarbons from amine, glycol, and wastewater streams. Ideal for supporting environmental compliance, chemical recovery, and polishing fluids prior to reuse or discharge.

Refinery Filtration Products Built for Performance

Our filtration products are engineered for high flow rates, harsh chemistries, and nonstop refinery operation. From replacement elements to custom housings, every solution is built for durability and performance.

High Velocity Flushing Service Saves Steel Manufacturer

Oil Flushing Services Needed After Catastrophic Downtime For the past 3 years, we have been working with a major steel manufacturer in supplying dedicated offline filtration equipment and MRO filter elements for their mill stand lube oil system. They had been needing...

Aviation Fuel Contamination: Types, Causes, and Removal

If there’s one thing every pilot, maintenance engineer, and fuel handler agrees on, it’s that clean, dry fuel is non-negotiable. Turbine engines and high-compression piston engines are unforgiving machines. A few drops of water, a few particles of dirt, or a trace of...

ISO Cleanliness Codes: Complete Guide to Oil & Fuel Standards

ISO cleanliness codes are the global standard for quantifying solid particle contamination in industrial fluids like oil, fuel, and hydraulics. This guide breaks down how ISO codes work, why they matter, how to interpret them, and how to achieve your target codes with...

Contact an Expert

Need assistance? PFP will help you solve your industrial filtration challenges.

Find us on Social Media

Connect with us on social platforms to stay in the know.